Built to Make Engraving Easy

Intuitive

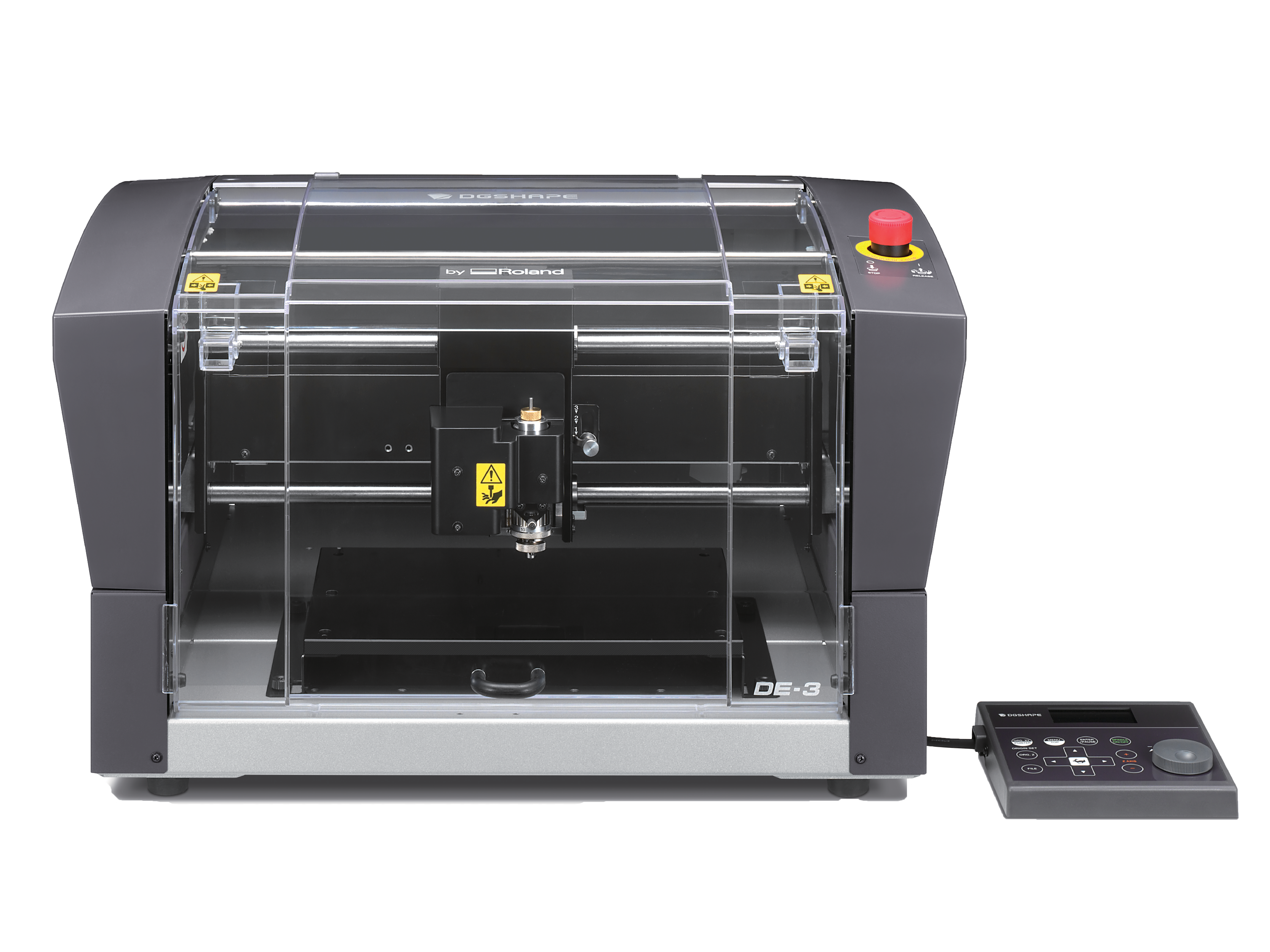

A large, red button is located right on top of the machine for those moments when an engraving job needs to be cancelled right away.

Without the need for a computer, you can quickly select machine options such as spindle speed and one-touch machine cleaning. Engraving job data can be sent from your computer and stored in the controller after the PC is disconnected.

Versatile

Using a split collet and rotating spindle, the DE-3 can produce traditional rotary engraving output on woo and synthetics like engraving plastics and acrylics.

The spindle motor can be disabled to turn your rotary engraver into a precision Diamond Drag tool for engraving on precious metals.

Combining Rotary and Diamond Drag technologies, Burnishing tools can leverage the power of specially designed tool bits and the spindle motor to create unique effects in coated metal substrates such as anodized aluminum.

DE-3 uses a laser pointer for precise alignment of materials on the work area. Eliminate trial and error in high accuracy engraving jobs by using the red dot to place materials exactly where they need to be.

No more wasted blanks, no more frustration.

Scalable

Connect DE-3 to your favorite chip removal system and keep your work area clean during engraving. The bundled air hose and clamp adapter fits right over the spindle and collects engraving waste while the machine is running.

DE-3 can be fitted with a Braille kit for producing raster braille Accessibility signage for the impaired.

DE-3 accepts an optional center vise for securing high-value and odd shaped items that need to be secured for engraving.

Professional Grade

Machine operation can be managed remotely on the DE-3— offering LAN network connectivity for multiple machine engraving.

Easy-to-apply nose cones can be added to the spindle unit to automatically regulate engraving depth on the media surface, delivering consistently precise results.

Included air hose fitting connects to Chip Removal systems to evacuate engraving waste on non-metal substrates.

Powered by a 20,000 rpm DC brushless motor, the DE-3 harnesses advanced surface detection and other automatic features to make set-up and engraving quick and simple.

A laser pointer accurately defines the origin point and displays an engraving path preview on the media – set the engraving position at the touch of a button.

Whether you are a sign-maker, equipment manufacturer, or awards and gift supplier, the DE-3 desktop engraver is ideally suited to engrave an impressive variety of giftware, signage, trophies, tools, and industrial products. The DE-3’s integrated safety cover and user-friendly operation also make it ideal for use within retail environments.

BUNDLED SOFTWARE

Import a spreadsheet of data to populate serialized applications such as name badges, awards, and industrial labels

Dr Engrave Plus supports advanced engraving functions such as bed leveling and hole drilling.