Lab Business Management Tool

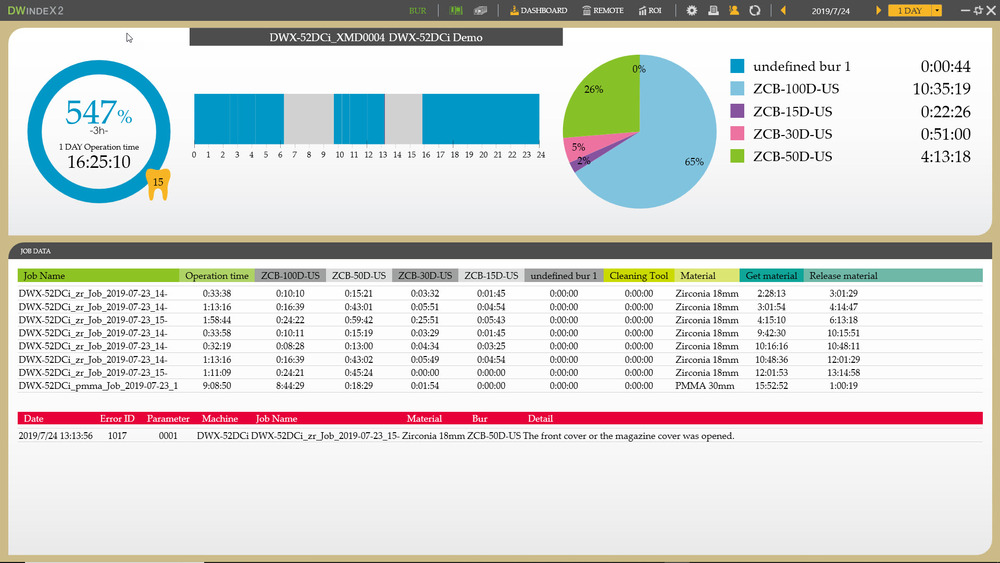

Dashboard

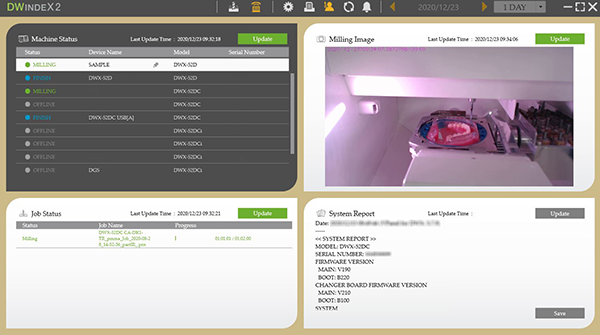

Remote

Email notifications

Centrally manage lab operations

Real-time management of the status of running DWX milling machines

By displaying the operation status of the milling machine and remote functions

・ It is difficult to predict the progress of the work,

overtime work does not decrease easily,

・The cause of the error is not understood,

and measures cannot be taken

Software that leads to the solution of such

problems. Get the most out of your DWX series performance.

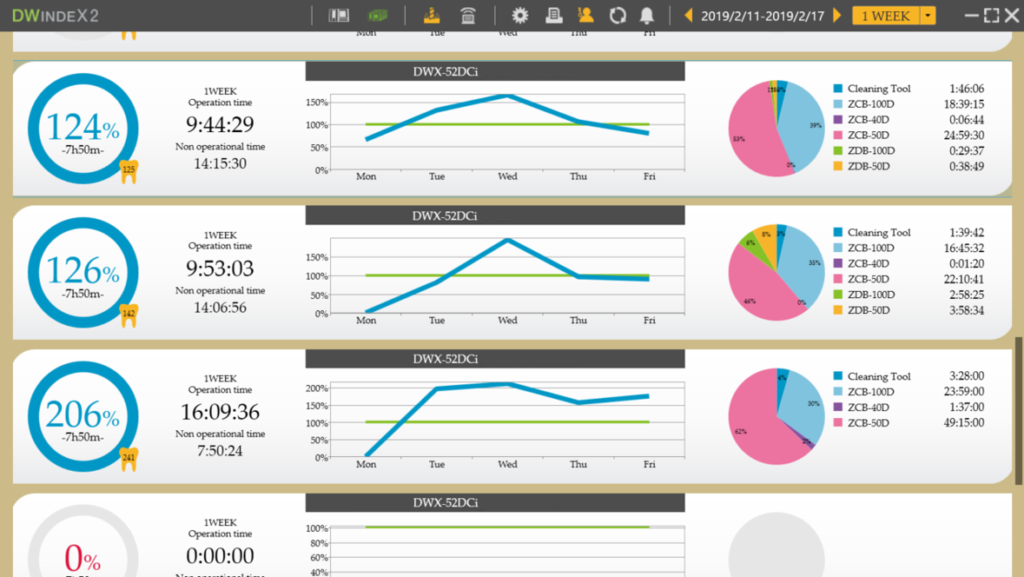

Even if you have multiple DWX-52D/DWX-52DC/DWX-52DCi/DWX-42W, you can analyze the uptime and uptime of all milling machines.

Get tips on how to get your milling machine up and running efficiently to increase productivity during business hours.

By using the following CAM software, it is possible to display the processing results even by the number of teeth.

・MillBox 2019 ver or higher

・hyperDENT DGSHAPE ver 8.2.3 or higher

* You can use DWINDEX2 even with non-compatible CAM software, but there are places where some data is not automatically reflected. By setting the material in VPanel, it is possible to see the material data.

It is possible to analyze the usage by type of material and milling bur used, processing time, and usage by aircraft. Useful for inventory management of materials and milling burs.

Understanding the life of milling burs and materials can help you accurately understand cost and productivity per machining and manage consumable inventory.

By managing and analyzing error logs, it helps to extract operational improvements and skill-up points for staff.

When was the last time you performed spindle maintenance?

Recording and visualizing maintenance history helps keep the machine in an optimal condition at all times.

Voice of the customer

“It is easy to understand by being displayed by day, week, and month how long it is milling”

“All registered milling machine can be monitored”

“The number of teeth in the week and working hours can be confirmed”,

“It is utilized when sharing working hours in meetings with other departments”,

“The percentage of materials used is summarized for each shade, and it is used as a reference for the number of material orders”

” It is easy to understand where the problem is because the contents are written when an error occurs”

“You can see at a glance what kind of errors are common”

Remote features

To operate the milling machine efficiently, there is no need to constantly monitor the machining status by the side. DWINDEX2 provides a perfect understanding of milling machine health and helps improve productivity.

Also, the PC connected to the milling machine is recorded in all of the cutting processes where the error occurred, which helps to determine the cause of the error.

If you are setting up your camera, you will receive an email with a link that will allow you to access a 40-second video clip when an error occurs. You can check the error status even when you are on the go.

Also, if the computer with VPanel installed is connected to the milling machine, all of the cutting steps that failed are recorded to help determine the cause of the error.

By setting it in VPanel, you can receive e-mail notifications when “finished processing”, “error occurred”, and “maintenance end”.

The “Error Occurrence” notification provides a link that allows you to access a 40-second video clip that records 30 seconds before the error occurs + 10 seconds after the error occurs. Besides, it includes notice of forgetting to work that may occur outside of troubles during processing, such as forgetting to put materials and milling burs.

There may be damage to the milling bur during machining, unexpected data errors, and troubles during long-term machining.

If the next data and material to be machined is prepared, you can skip the remotely troubled machining and continue machining.

Voice of the customer

“I’m using the email notification function, it’s very good.

I was notified by e-mail that I forgot to put the disc when I went out”

“It is convenient to understand the operation status even if I leave the workplace at night”

“It is good to be able to grasp errors such as error recording and use it”

“In case of trouble, even if you can not respond by yourself, it is good to be able to check the trouble occurrence situation”

- FAQ

Click the button below to go to

a web page that will show you how to set up DWINDEX2.