Fortschrittliche Trockenfrästechnik

Mehr von dem, was Sie benötigen

TECHNOLOGIE

Fünfachsige Dentalfräsen in höchster Vollendung

Die DWX-52D Plus Trockenfräse bringt Ihre Produktion auf ein neues Niveau. Mit schnellerem Ergebnis, verbesserter Präzision und neuen Werkzeugen und Methoden wird das Fräsen von Zirkoniumdioxid, PMMA und anderen Materialien einfacher, effizienter und genauer als je zuvor.

VIELSEITIGKEIT

Ein Gerät

für unterschiedlichste Materialien

Mit der 5-Achsen-Dentalfräsmaschine DWX-52D haben Sie die Freiheit, Material und Anwendungen zu wählen. Fräsen Sie mehrere Anwendungen aus Zirkoniumdioxid, Wachs, PMMA, PEEK, PEKK, Gips, Verbundwerkstoff und Chrom-Kobalt-Sintermetall. Laden Sie scheiben- oder stiftförmige Materialien. Fortgeschrittene Anwender können den Arbeitsablauf für herausnehmbare Prothesenkits hinzufügen, um ihre interne Produktion von Teil- und Vollprothesen zu digitalisieren. Mit dem DWX-52D sind Ihre Möglichkeiten unbegrenzt.

Steigern Sie Ihre Produktivität

Übernehmen Sie die Fernsteuerung Ihres CAD/CAM-Fräsgeräts mit DGSHAPE CLOUD: Ihre kostenlose Software. Erfahren Sie mehr und laden Sie Ihre Version herunter.

Performance

Hochgradig optimierte Produktion

Bei den heutigen hohen Produktivitätsstandards ist es wichtig, den Überblick über Ihren digitalen Workflow zu behalten, auch wenn Sie nicht am Arbeitsplatz sind. Unsere neueste Leistungssoftware hilft Ihnen, die Produktion zu optimieren und das Beste aus Ihrem Gerät herauszuholen. Behalten Sie den Überblick über laufende Aufträge, fertiggestellte Aufträge und die Gesamtauslastung Ihres Fräsgeräts. Mit der DGSHAPE CLOUD Performance Monitoring Software können Sie die Material- und die Werkzeugauslastung genau verfolgen, den Support verbessern und vieles mehr.

PRÄZISION

90°-Fräsen

Der Open-Edge-Adapter (ZMA2-52D) von DGSHAPE ermöglicht präzises Fräsen für alle Ihre zahnmedizinischen Anwendungen. Stellen Sie eine saubere Gesichtsanatomie an der Frontzahnoberfläche einer jeden Krone oder Brücke her. Entfernen Sie Unterschnitte mühelos, während Sie aus jedem Blickwinkel auf weitspannige Brückenrestaurationen zugreifen. Nutzen Sie die offene Seite des Adapters für zusätzlichen Platz zum Einsetzen breiter Brückenbögen oder chirurgischer Schablonen, die beim Fräsen von Zugangslöchern eine bessere Neigung erfordern. Mit der 5-Achsen-Dentalfräsmaschine DWX-52D sind Ihren Möglichkeiten zum Präzisionsfräsen keine Grenzen gesetzt.

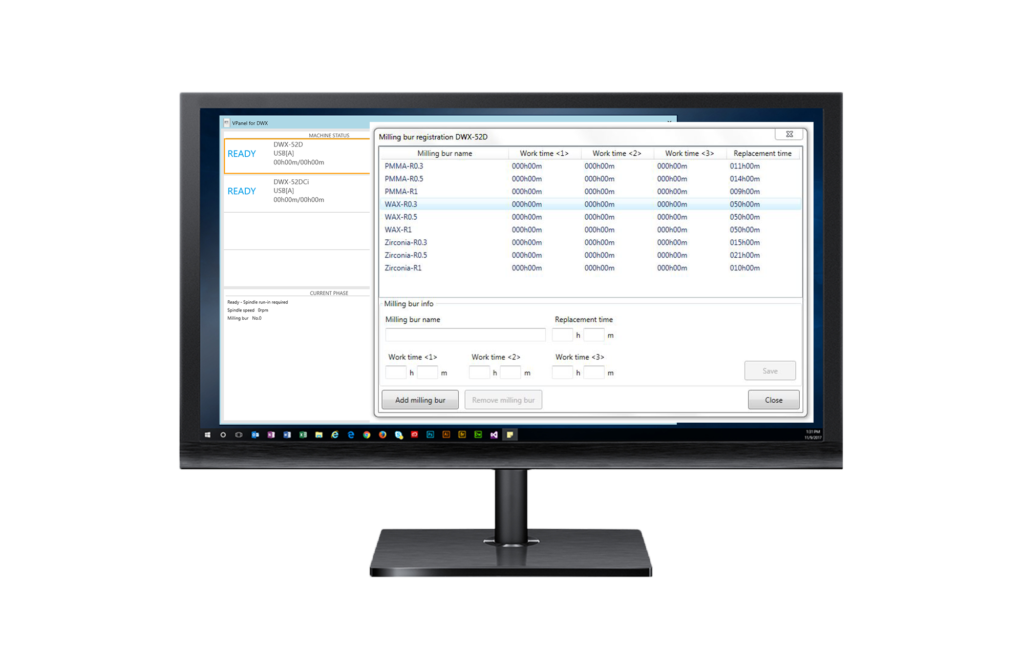

BETRIEB UND WARTUNG

Vereinfachte Produktion und Geräteüberwachung

Die mitgelieferte VPanel-Software bietet eine Komplettlösung, die Wartung und Leistungssteuerung nahtlos miteinander verbindet. Mit VPanel können Sie Ihr Fräsgerät aus der Ferne überwachen, ohne dass sich ein Bediener in der Nähe aufhalten muss. Sie können den Einsatz der Werkzeuge überwachen und Benachrichtigungen festlegen, so dass Sie wissen, wann Fräsaufträge erledigt sind, Operationen abgeschlossen sind oder ein Fehler aufgetreten ist. Überwachen Sie bis zu vier Fräsgeräte von einem einzigen PC aus, und führen Sie alle Wartungsarbeiten über die benutzerfreundliche Oberfläche von VPanel durch und verfolgen Sie sie.

DGSHAPE Crew

Anytime, Anywhere on Any Device