Wet Milling Reimagined

Engineered to Exceed Your Expectations

QUALITY

The Precision You've Been Looking For

The new DWX-42W Plus Wet Mill is designed to exceed your expectations. With faster milling times, longer tool life, new CAM strategies and a stronger system, it makes milling fully sintered zirconia Blocks and hybrid ceramic materials more efficient and accurate than ever before.

Versatility

Bring Custom Abutment Milling In-House

Paired with the AK-1 Abutment Milling System, the DWX-42W offers a complete solution for milling custom abutments from titanium blanks produced by popular manufacturers like DESS, NT-Trading, MEDETiKA®, and GeoMedi. Custom titanium abutments are easy to produce in-house using the DWX-42W and AK-1 Abutment Milling System. Switch in minutes to production of custom abutments, avoiding the hassles of outsourcing and making the production process faster, more convenient and more cost effective than ever.

Efficiency

Mill Multiple Restorations At Once

The DWX-42W can simultaneously mill up to three ceramic units. Boost your productivity even further with DGSHAPE’s Multi-Pin Clamp (ZV-42W, sold separately). The Multi-Pin Clamp holds up to six ceramic blocks, upgrading your mill’s capacity and maximizing your workflow efficiency.

Performance

Incredibly Fast Output

DGSHAPE’s latest Wet Milling Machine features a new, heavy-duty spindle and requires only 0.22 MPa of compressed air, eliminating the need for a separate air compressor. It also offers multiple milling techniques to speed up production for all dental applications. Mill up to three restorations simultaneously for the fastest production times, or add the multi-pin clamp to mill up to six restorations at a time. Select multiple tools to produce high-quality crowns, veneers, small bridges, inlays, onlays, and screw-retained applications.

Operations & Maintenance

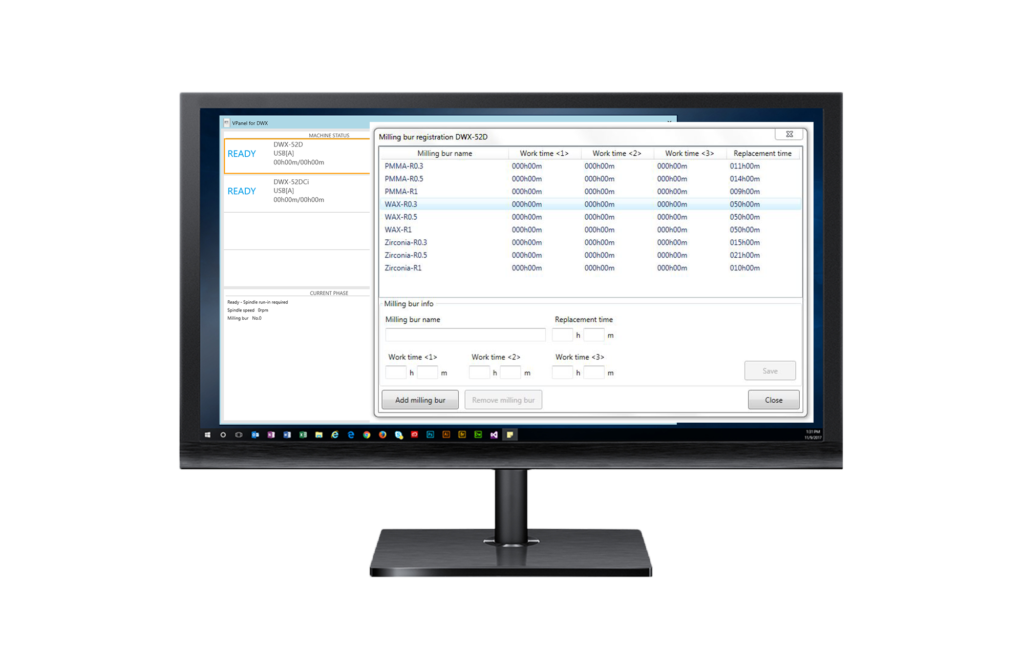

Simplified Production and Device Monitoring

Included VPanel software provides a complete solution that seamlessly combines maintenance and output performance control. Use VPanel to remotely manage your milling device without any need for an operator to be stationed nearby. Monitor tool use and set notifications so you know when milling jobs are done, operations are completed, or when an error has occurred. Oversee up to four milling devices from a single PC, and perform and track all maintenance operations through VPanel’s user-friendly interface.

Anytime, Anywhere on Any Device

Interested? Request a free demo

Find a Dealer

Our DGSHAPE Authorised dealers are carefully selected, and offer superior expertise and tailored advice across a range of DGS products and services.

By filling out the form, we can ensure:

- A no-hassle process, a dealer will contact you right away

- We match your needs to the dealer who has the best expertise to support your business CAD/CAM needs in the base of your country

- You won’t waste time trying to find the right dealer around the world

- You are buying genuine, authentic DGSHAPE services and supplies